By the end of the year, the Vrchlabí component plant is set to become the first Škoda Auto site in the world to produce in a CO2-neutral manner. The greatest carbon dioxide savings have been made by converting the high-tech factory in Czech Republic to the use of renewable energies – reducing CO2 emissions from an initial 45,000 tonnes per year to a current 3,000 tonnes.

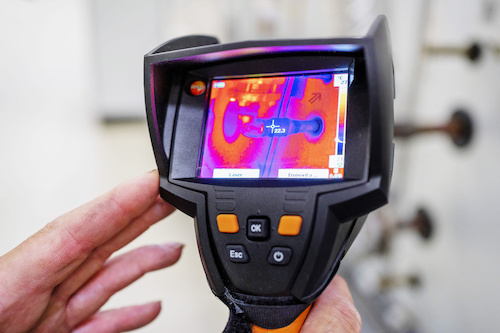

Comprehensive and specific energy-saving measures have been key in particular during the process of converting the component plant to CO2-neutral production. Through the renovation of the factory’s heating system alone, it was possible to reduce the annual energy consumption by 6,700 MWh in 2012 and 2013 – the largest individual saving to date.

Since the beginning of 2020 the plant has been pursuing twelve projects that will save more than 2,000 MWh of thermal energy and almost 1,800 MWh of electricity in total. These include measures such as closing unused heating circuits, regulating room temperatures to save energy and specifically regulating the supply air flow. In addition, the lighting in numerous areas of the factory premises is linked to operating hours.

Škoda Auto is also rigorously capitalising on alternative energies to reduce CO2 emissions at its Vrchlabí site. The factory requires around 47,000 MWh of electricity each year for production; more than 88% of this now comes from renewable sources. Natural gas is the only remaining fossil fuel used; this will be gradually replaced by CO2-neutral methane from biogas plants as of 2021. The remaining carbon emissions are to be offset through compensation measures and the purchase of CO2 certificates.

Source: Škoda Auto